Oyster production (WP2)

The aim of work package 2 is to create conditions for a stable high production European flat oysters.

Background and aim

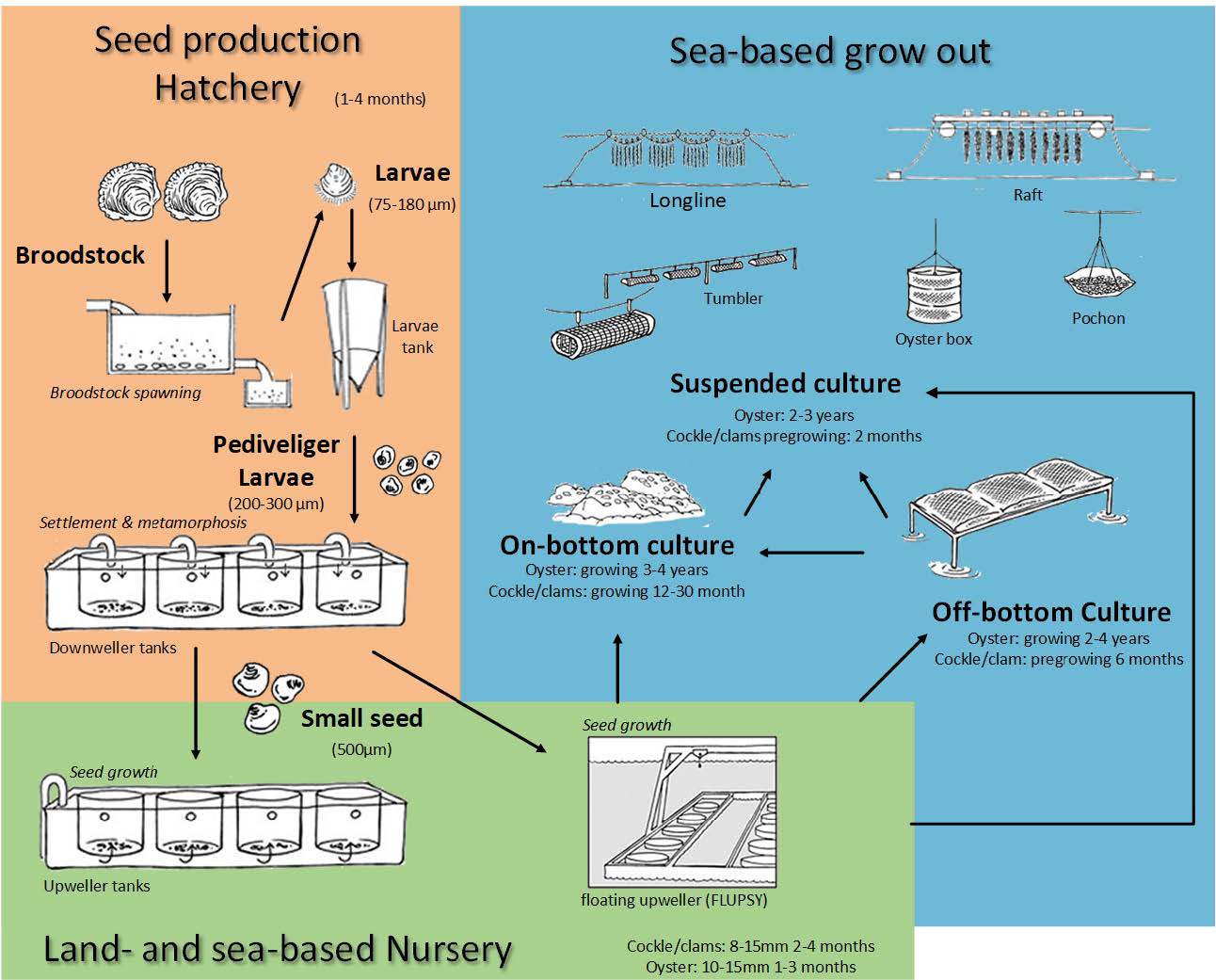

The two key bottlenecks for flat oyster production are disease-free hatchery produced seeds and grow out systems adapted to Danish environmental conditions.

The oyster broodstock in Denmark is only present in Limfjorden, which is not Bonamia disease-free. This means that infected oysters should not be transported to areas where the disease is not present.

The aim is to produce a high-volume of disease-free spat as seeding material for grow out in Limfjorden and also areas outside, optimization of support functions like microalgae production and biosecurity measures (see work package 4) and development of new methods for on-land and is situ grow out.

Tasks

WP2 will lead the Danish flat oyster aquaculture production to a commercial size by optimizing culture methods and thanks to new technologies will upscale microalgae production via the following six tasks:

- Innovative establishment of Bonamia-Marteilia-free broodstock.

- All year-round seed supply.

- Algae feed.

- Optimization of feeding protocol for oyster production.

- Cultivation system on land for small spat.

- Technology development and test of grow out structures.

Partners

- DTU Aqua (lead of WP2)

- AlgaSolis, University of Nantes

- Aliga

- Muslingeriet

- Oyster Boat

- Kerteminde Seafarm

Learn more about the partners in LTA BOOST